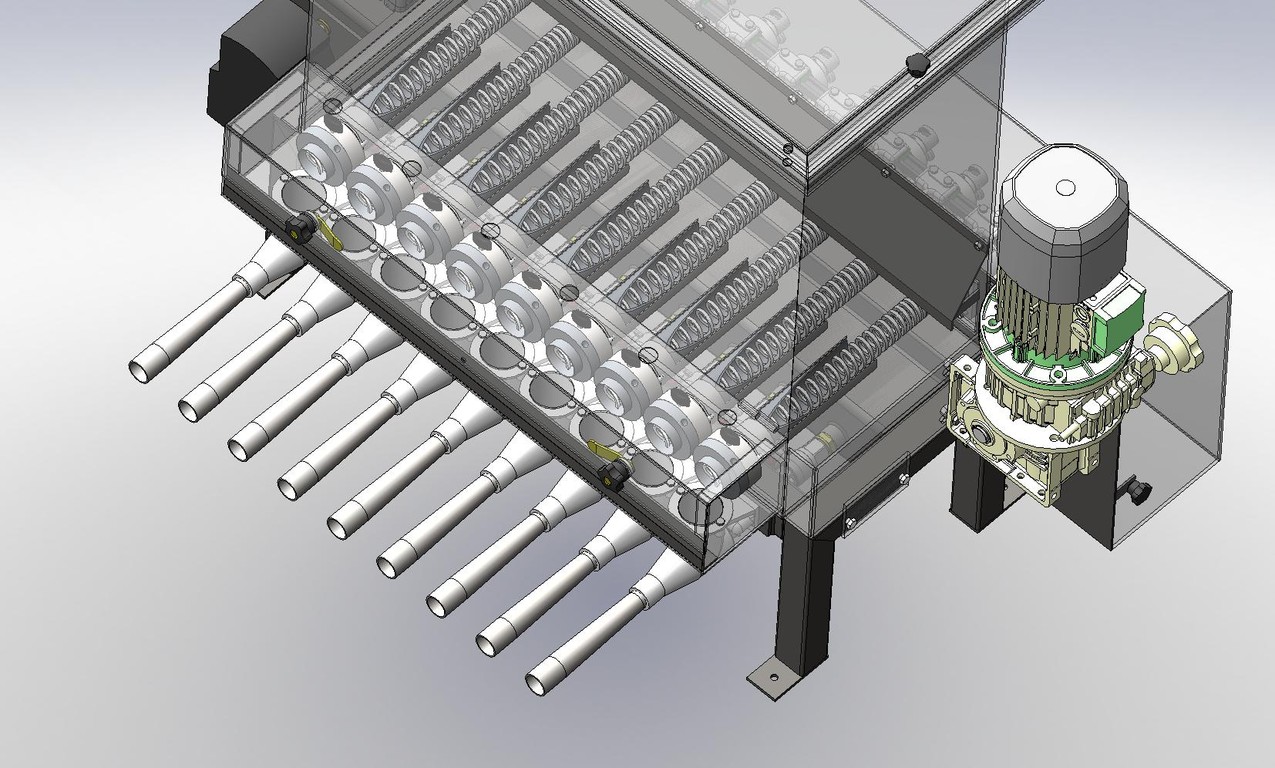

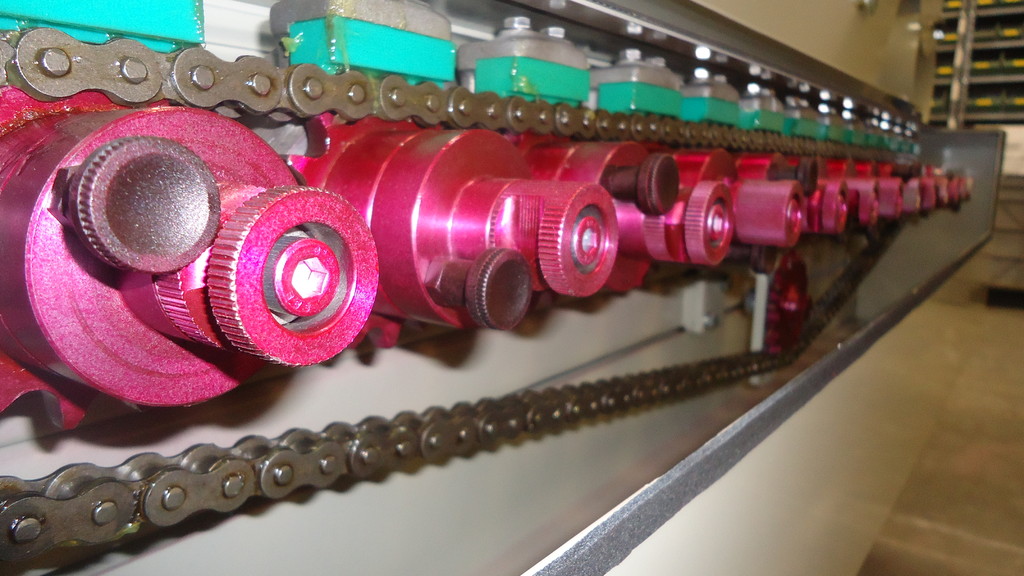

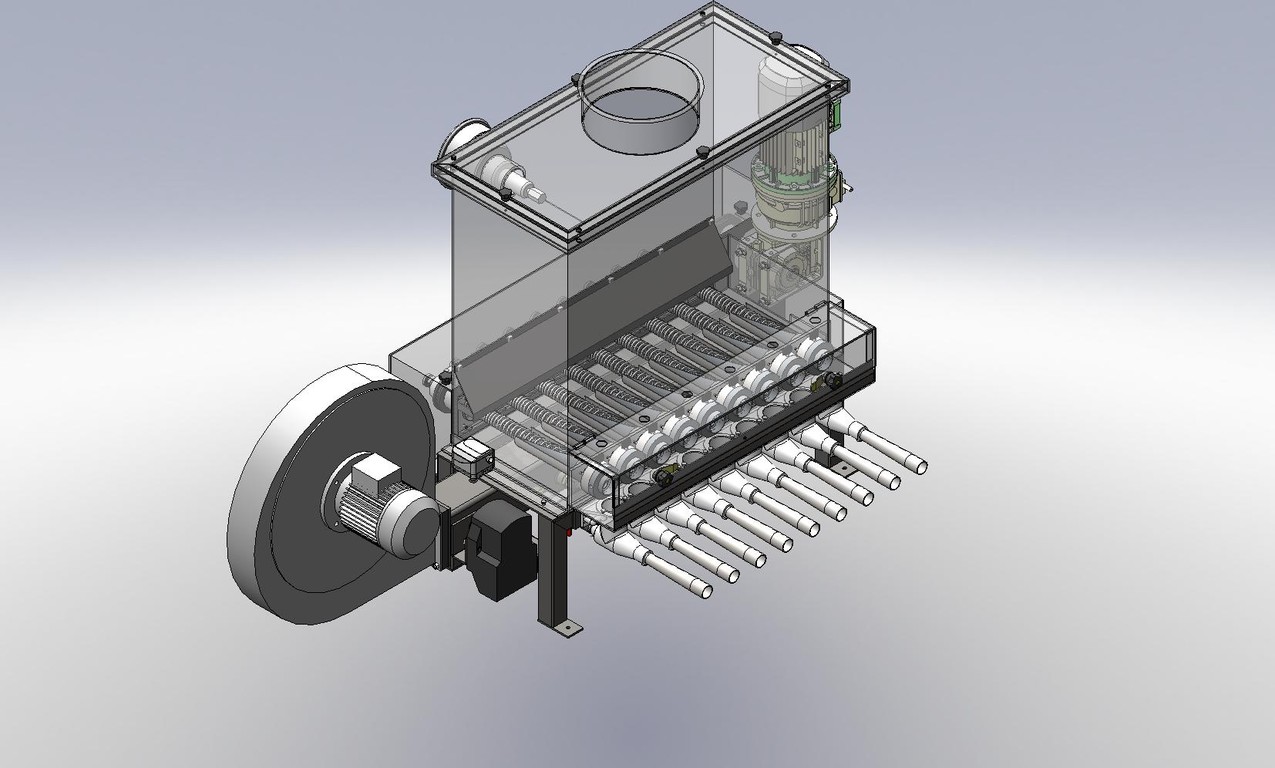

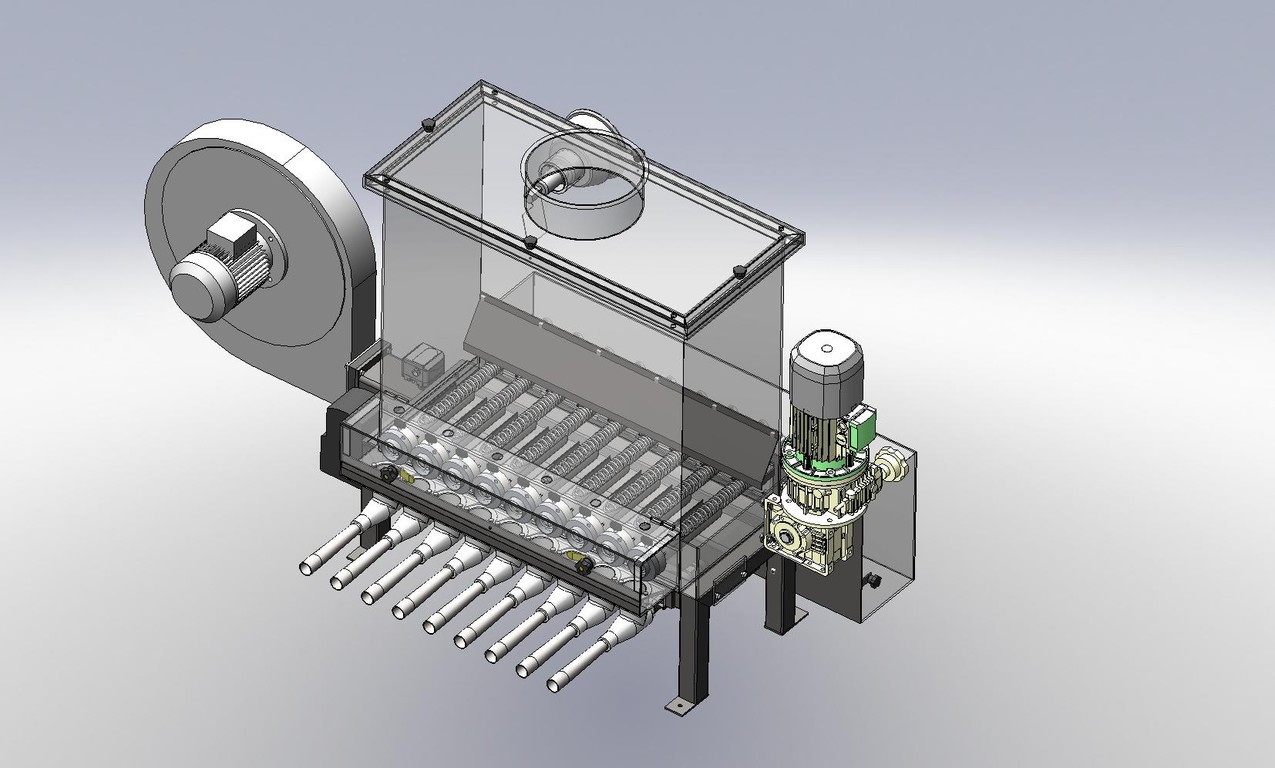

The machine is composed of a structure containing a tank of xxx m3, and a base with a number of openings equivalent to the number of feeding fire openings of the burner. On the structure are applied dosing systems and dust transportation toward each venturi pipe, the fan for air conveying and combustion, the motorization. A single motor drives the rotation of each auger which are at the service of each feeding pipe.

The adjustment of the quantity of fuel per rod is done manually by means of the calibration of the dosing system relevant to each rod. The adjustment of air quantity for each rod happens by adjusting the corresponding valve.

Each burner is equipped with an overflow sensor (which intervenes with the closing of the inlet valve), control panel, temperature detection thermocouple.

Each burner is equipped with a control system of the pulverized coal and air amount for each feeder, so as to give an optimal fuel / air ratio, in addition to the required amount of air-fuel mixture with regard to each feeder according to the need in the feeder working area.

Special features of the firing installation are:

- Limited space on the floor of the kiln

- Loading hopper with automatic level control

- High pressure centrifugal fan with adjustable pressure and flow

- A fuel feeding system controlled on the basis of the set temperature

- Control on each feeder of the amount of fuel and the fuel / comburant ratio