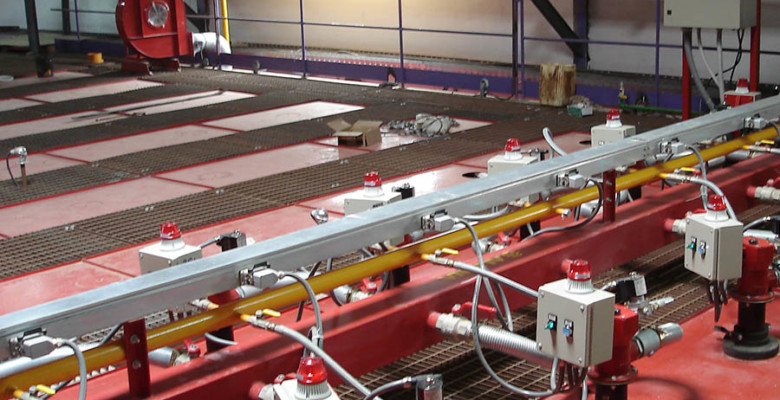

High-speed feeding system, composed by 8 up to 16 self-igniting burners are mounted on the kiln flat arch and can be fuelled with natural gas, Coal gas or LPG in the automatic control system. They are designed to work in the 600°C to 800°C critical kiln area to bring the material to ideal conditions in the firing initial stage.

Fitted with an independent ignition and flame control system, the ALPINA FIAMMA burners, can work with any temperature inside the kiln and can therefore be used also on initial kiln firing or in case of kiln start after shut down with no need to build any special devices.

The highspeed flame together with its remarkable penetration are a further guarantee for the removal of any unburnt gas and allow a very good prefiring with a gradual temperature rise in the firing initial zone. The result is an increase in production and a better product quality.

Thanks to the electronic ignition system (without the dated ignition with pilot burner) and the innovative electronic control circuit ALPINA FIAMMA burners have firing points independent of each other.

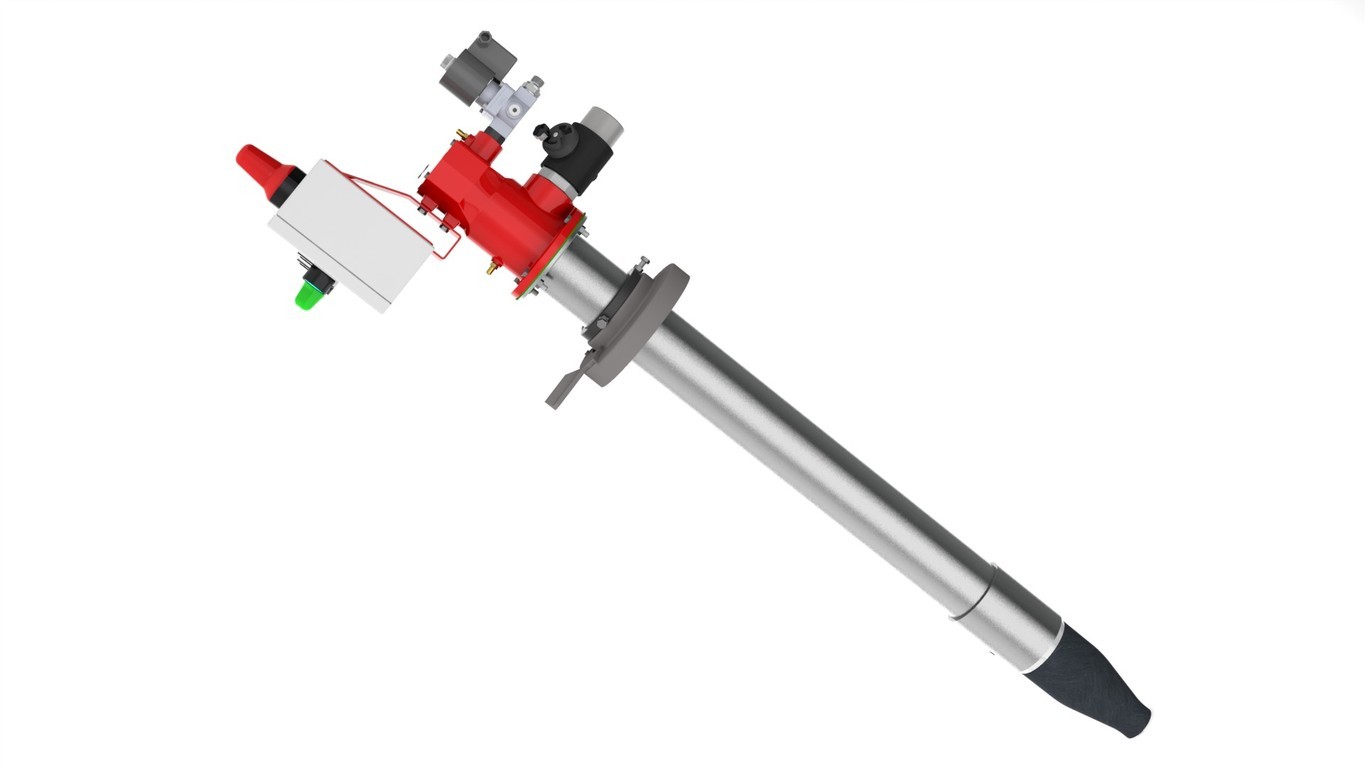

The electrical control box on board of the equipment manages the modulating valve of gas and of combustion air and the ignition of each individual burning injector, controlling flame presence and its quality.

ALPINA FIAMMA burners are made up of:

- High-head fan unit

- Air/gas powered valves for the automatic modulating regulation, with air presence safety pressure switch

- Security Gas manifold and distributor complete with cut-off valves and pressure gauge •

- Flame control and ignition with gas flow solenoid valve

- Stainless steel combustion chamber with silicon carbide head