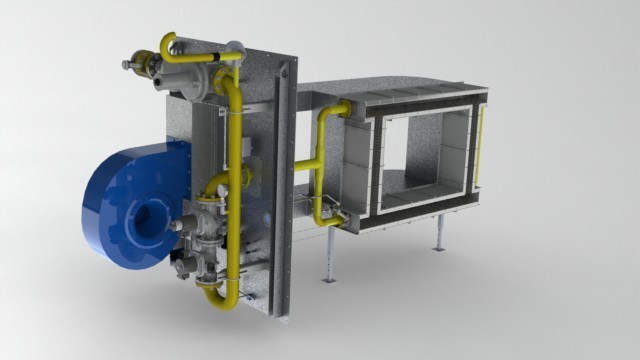

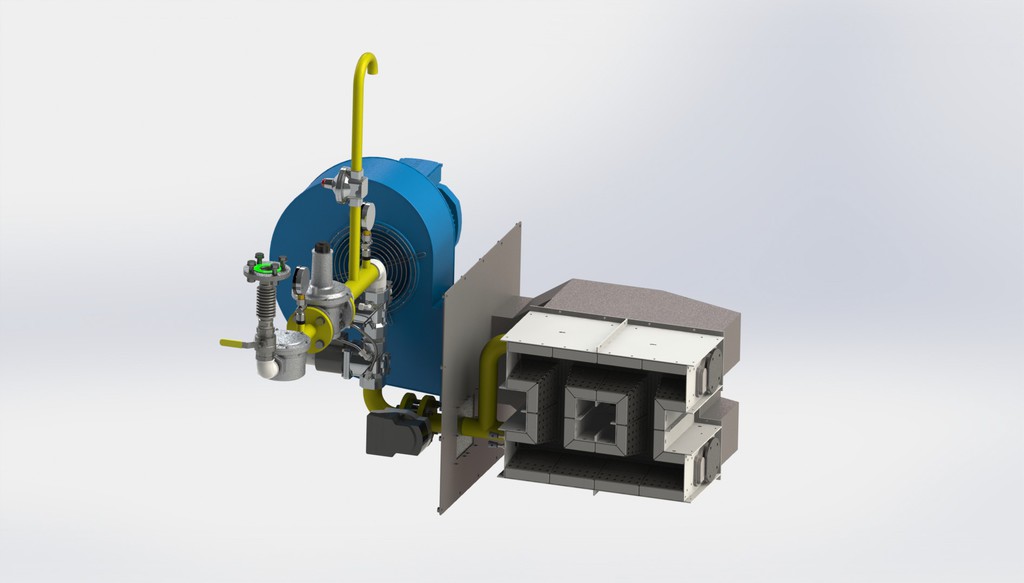

HOT AIR GENERATORS – BVA type – indirect air

The hot air duct gas burners (natural gas, LPG, mixed gas, biogas etc..) in the two application systems BVA S and BVA N operate within an air stream. They consist of modular “modules” which, according to the power required and the required application, allow to use the system in many types of installations.

The large adjustment ratio, allows to reduce the power, ensures rapidity of intervention, working precision, limited thermal dispersion, emissions reduction.

They are produced as standard models BVA S, complete of a combustion air fan which is enough to

generate the complete combustion, or without combustion fan, model BVA N, so as to use the process air as combustion air.

In some cases, where the use of external air is not compatible with the process and the process air speed is not enough, you can use the combustion air fan that draws air directly from the process, provided that the presence of oxygen in the process is sufficient for combustion.

The burners are supplied as complete ones with the necessary safety ramps and control and relevant control panels built in compliance with the regulations in force in the countries where they are to be installed.

Power: From 50 kW to 30 MW

The modular structure allows to reach power values within the MW. The modular structure also allows the adjustment of the burner to the various geometry ducts.

High adjustment range: You can get the adjustments from 1:10 to 1:40.

Reduced length of the flame: The flame length is constant with reference to the maximum power output. The flame length also depends on the speed of the process air.

High temperature uniformity: For the temperature uniformity are important both air speed and the specific load of a burner module.

Temperature process: from 60 °C to 800 °C

Combustion chamber: BVA S series can be supplied with combustion chamber with standard sizes, or can be provided on suitable plates to be fixed on an existing duct whose dimensions are subjected to verification.

Combustion with reduced emissions: thanks to the particular configuration of flame modules, which allow an optimal mixing of air/fuel, these burners guarantee the emission values lower than those required by law.

SUPERTEC FIRE BVA are the gas heat production systems designed to operate within an air stream and they are composed of modular “modules” which, according to the required power and the required application, allow to use the system in any type of plant.

The large adjustment ratio, which is the possibility to vary the thermal capacity from 1 to 20 times ensures rapidity of intervention, working precision, limited thermal dispersion, reduction of emissions and therefore high thermal efficiency, high efficiency and lower consumption.

There are many applications of this product that range from the ceramic and heavy clay industry to the industry of food, textiles, chemical industry, paper and agriculture industry etc..

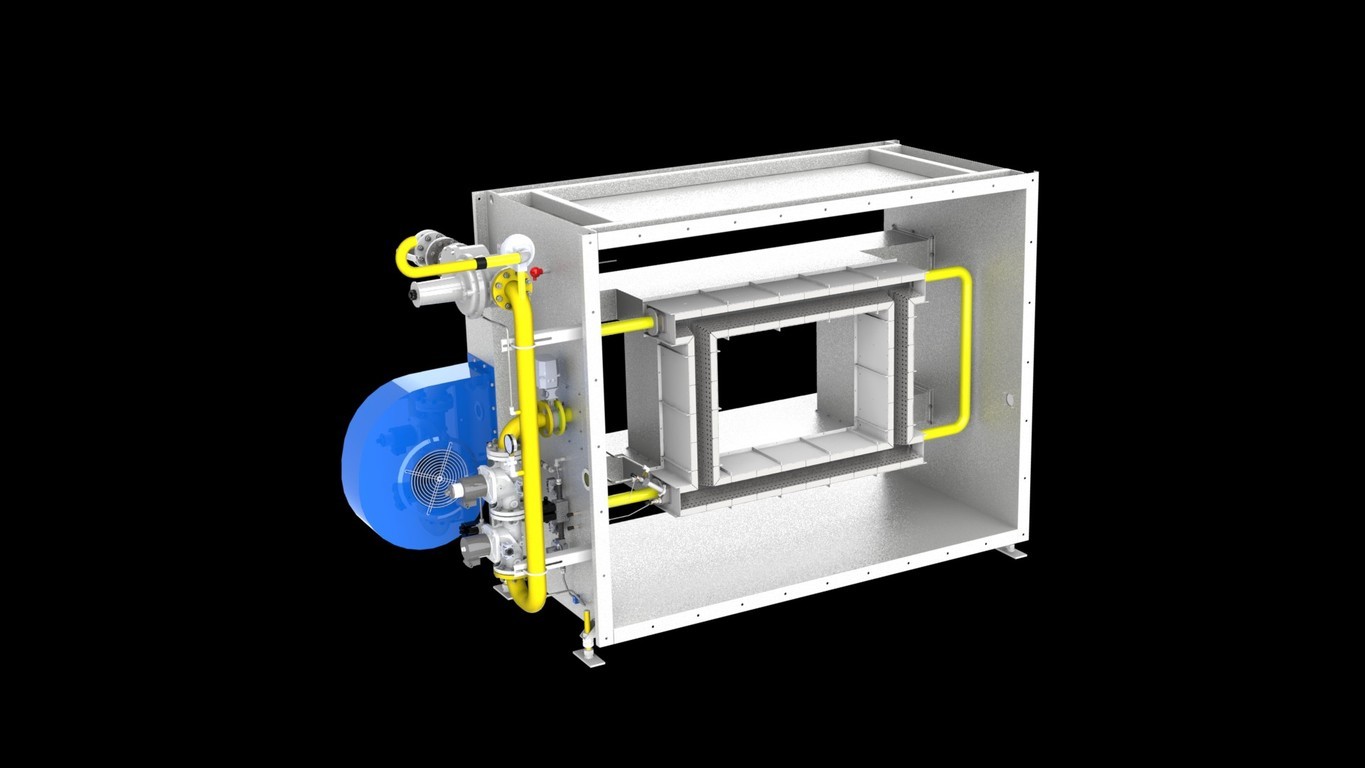

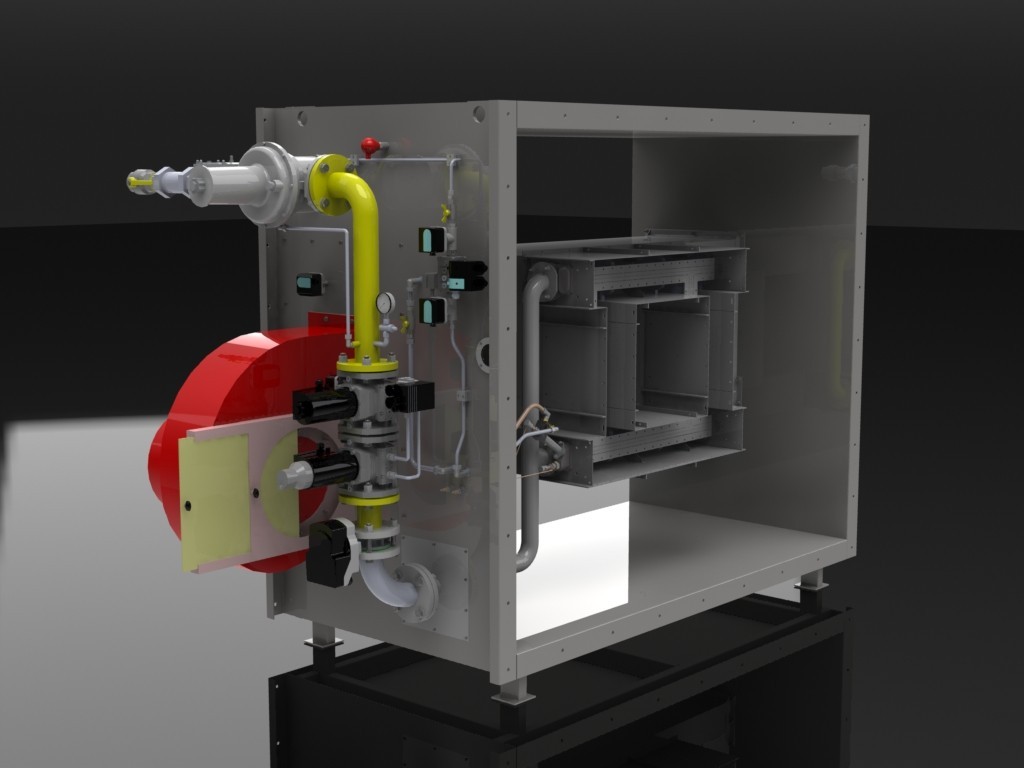

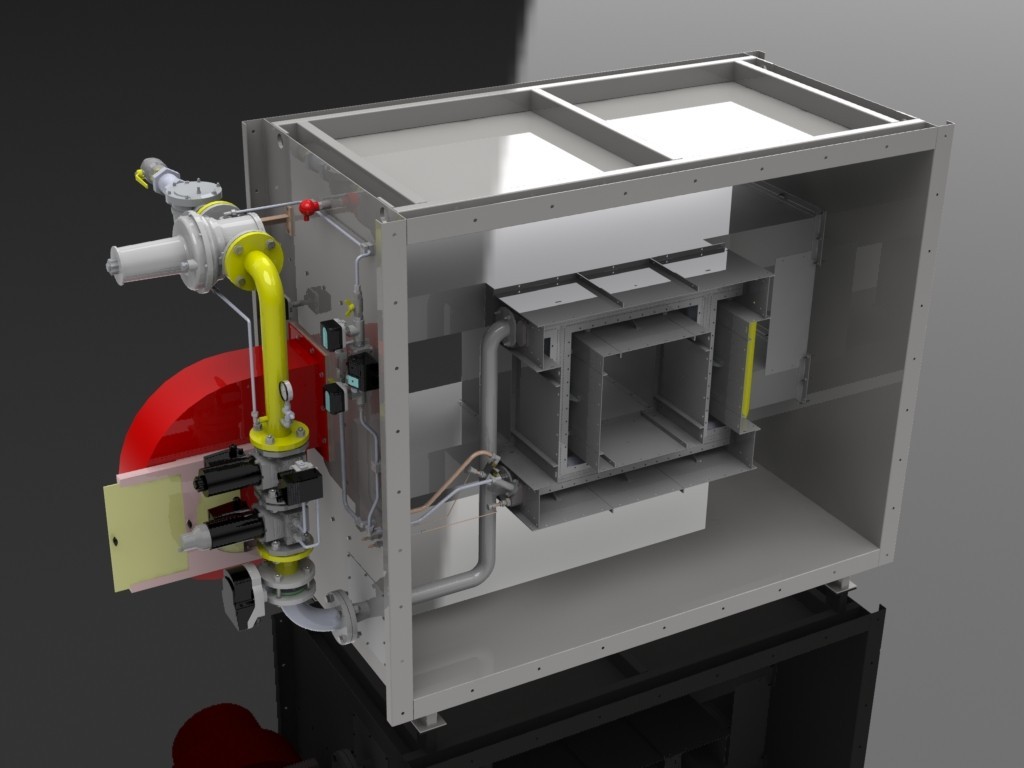

The burners feeders SUPERTEC FIRE BVA S consist of:

- frame made of modular units in steel sheet protected with resistant paint against high temperature

- burner body consists of modules in modular cast iron modules, which are linear and T shaped, with high resistance to heat and wear, bolted together in sequence and on them are applied by means of bolts the air conveyors deflectors in stainless steel.

- High pressure centrifugal fan for conveying of combustion air

- Ramp group of valves to control and modulate air / gas Min-Max

- Pilot fiamma group (only for models with capacities over 1,800,000 Kcal / h)

- electric board to drive and control

- PT100 thermal resistances

- Barrel with safety pressure switch to be inserted in the air duct

Example of the composition of a hot air heat generator:

- Basic linear element in cast iron constituting the gas pipe complete of central holes for the gas outlet and the two series of lateral holes for the exit of the combustion air

- Connection of two linear and T shaped elements in cast iron

- Application of stainless steel deflectors for conveying of combustion air

- View of the element formed by the basic elements in cast iron and stainless steel deflectors

- View of the element formed by the basic elements in cast iron and stainless steel deflectors

- View of the element formed by the basic elements in cast iron and stainless steel deflectors

- Back view of the connection between the elements in cast iron and stainless steel baffles

- Detail of the burner

- Detail of the burner

- Rear detail of the burner with the flame arrester network

- Section detail of the burner

- Section detail of the burner

- Detail of the spark and flame control