high-speed (150 – 200 m/sec), self-igniting side burners are mounted on the side wall of the kiln and can be fuelled with natural gas, Coal gas or LPG in the automatic control system. ALPINA SIRIO burners have three main functions: thanks to high speed they generate the turbulence required to mix the burnt gases with the air in the kiln. The high-speed flame, indeed, together with its remarkable penetration are a guarantee for the removal of any unburnt gas. They make temperature distribution uniform in the kiln zone where there are mounted and ensure even heating of all the layers of stacked materials and of the car lining allow a quicker and controlled rise of the material temperature. Thanks to the electronic ignition system and the innovative electronic control circuit each firing point of ALPINA SIRIO burners is independent of the others and can normally operate also with lower temperatures than fuel auto ignition’s (700°C); this means they can be used in the pre-heating zone as well as in the firing zone.

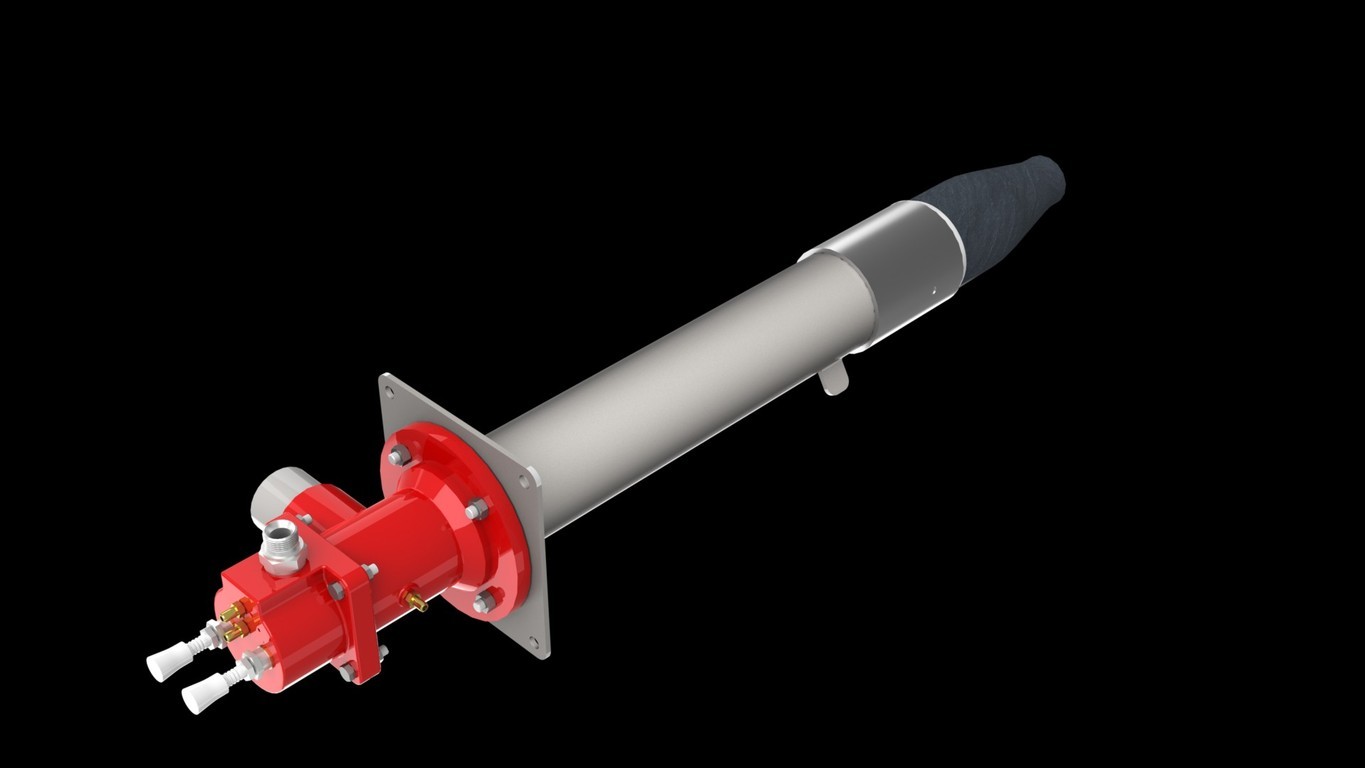

ALPINA SIRIO burners are made up of:

- High-head fan unit

- Cast iron head with ignition and detection electrodes

- Stainless steel combustion chamber with silicon carbide head

- Stainless steel guide housing complete with fixing support

- Min – Max – Stop variable flow gas regulators

- Min – Max variable flow air regulation solenoid valve

- Air/gas hoses and mounting and fixing accessories

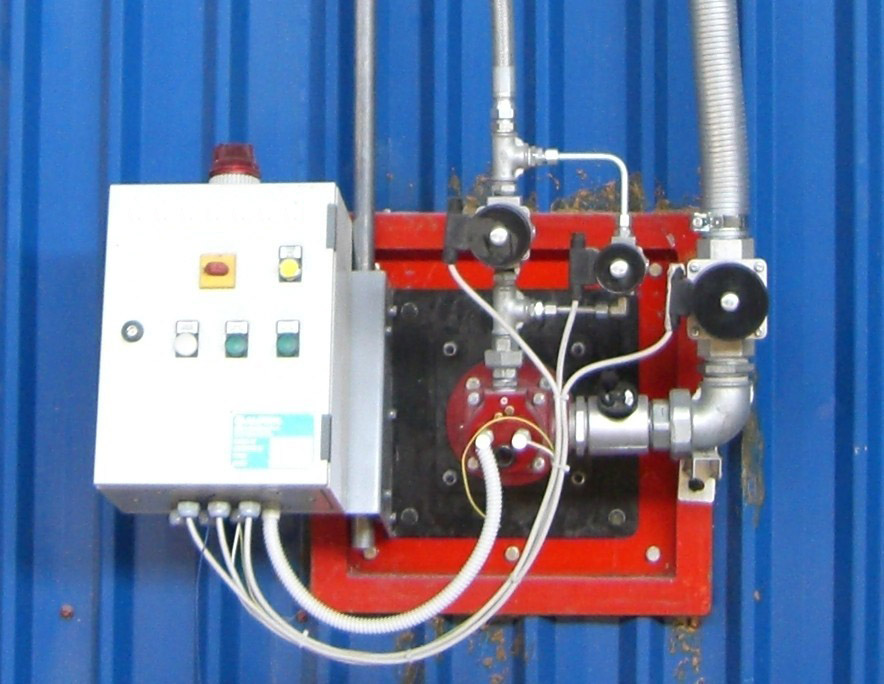

- Combustion air manifold distributor complete with manual cut-off valves and pressure gauge

- Gas manifold distributor complete with manual cut-off valves and pressure gauge