The gas burner rack “ORION H/8 Q” has been specifically developed by ALPINA INDUSTRIALE for the market of all the geographic areas where the production of bricks is based on the use of Hoffmann-type kilns with removable roof.

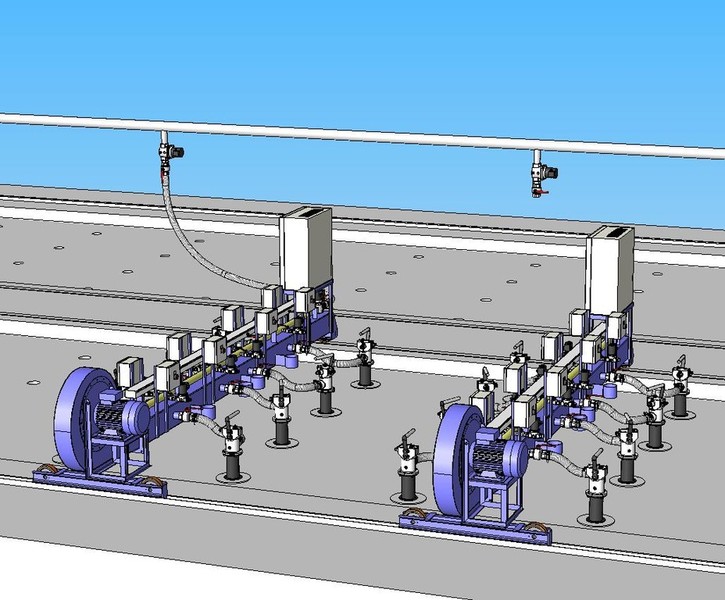

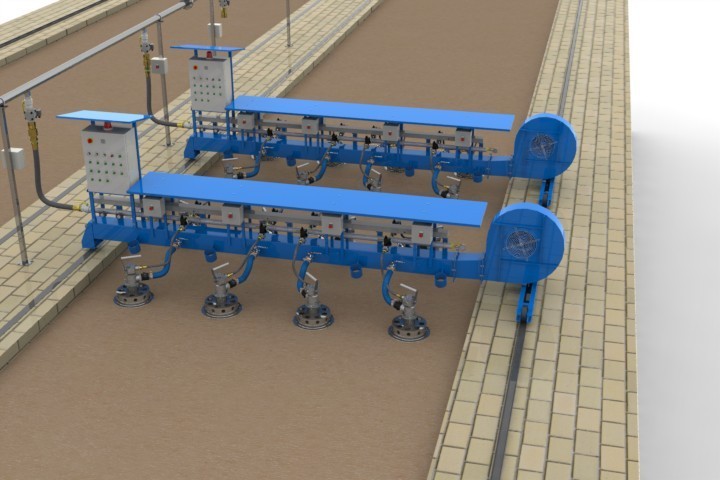

For this kind of kilns the use of mobile racks is necessary to permit the fast and safe moving, positioning and removal of burners. The rackruns on a lateral track placed by the side of the kiln roof; a hooking system allows removing and fastening the burners in raised position during the movement.

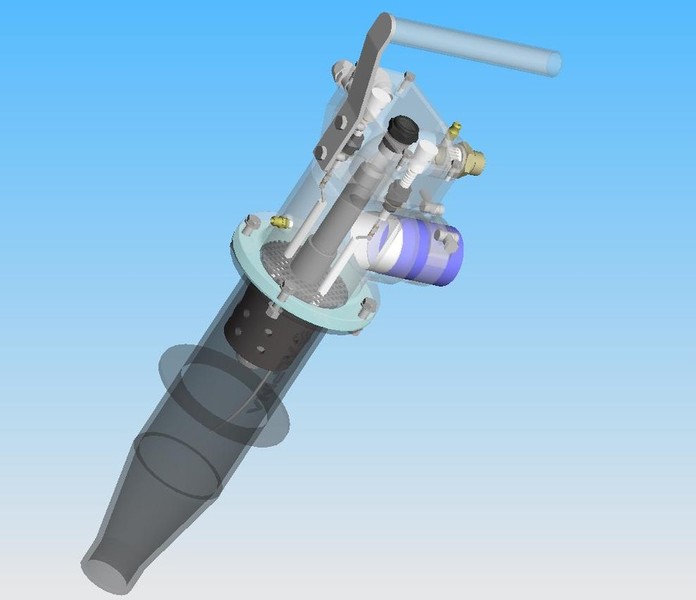

“ORION H/8 Q” feeds 8 high-speed gas burners operating with natural gas and GPL. The burners are equipped with self-ignition system with flame control and therefore are able to opérate in autonomy and total safety: each burner injector is independent from the others, since it is equipped with solenoid valve and an electric panel to drive and control the equipment. The presence of the flame control system also guarantees the absence of any unburned gas in the smokes.

Through a time controller of burner operation it is possible to fix the working time of the gas burner rack in its position, once expired, the gas feeding is interrupted and the operator Will proceed to move the rack to the following noe position.

Each burner introduces the combustión gas into the kiln at an average speed of 130 mt/sec and has three main functions:

- Uniform temperatura distribution in the kiln sections thanks to turbolence generated by high velocity and by the remixing of combustión gases with environmental air

- Uniform heating of all material layers

- Faster material warming because of higher thermic exchange coefficient due to friction created by air speed

This is a very efficient application of an automatic system in a background where the intervention of an operator is anyhow required. This systemm will help the efficiency of the combustion, as well as the improvement of health and safety conditions thanks to the drastic reduction of the emission of polluting substances.

ADVANTAGES OF ORION H/8 Q

- Efficiency and reduction of fuel consumption and maintenance costs

- Cleaner technology in comparison of mazout fuel or coal: reduction of hydrocarbon, sulphur dioxide (SO₂), Carbon monoxide (CO)

- Improvement of health and safety conditions

- Flame control system: interruption of gas supply under fault conditions

- High flame speed and difusión capability

- Fast and easy positioning of burner units thanks to the compact, light and resistant structure of burners ( only 11 kg per burner )

- Long durability of machine due to the high quality components